Most people when asked what a Core Drill is will think of a special hollow drill bit which can drill out a large hole in wood, stone or metal. The drilling process results in a core of the material being produced and the device in effect trepans out the actual hole. Depending on the circumstances a magnetic drill, a stand-alone drill secured to, for example the wall, or a “Black and Decker” may be used to drive the bit.

A search on the “web” will produce lots of information regarding this process and very little with respect to what we might call a proper engineering core drill. This is a pity as these drills are extremely useful and once you have tried one there is no going back.

So what are they?

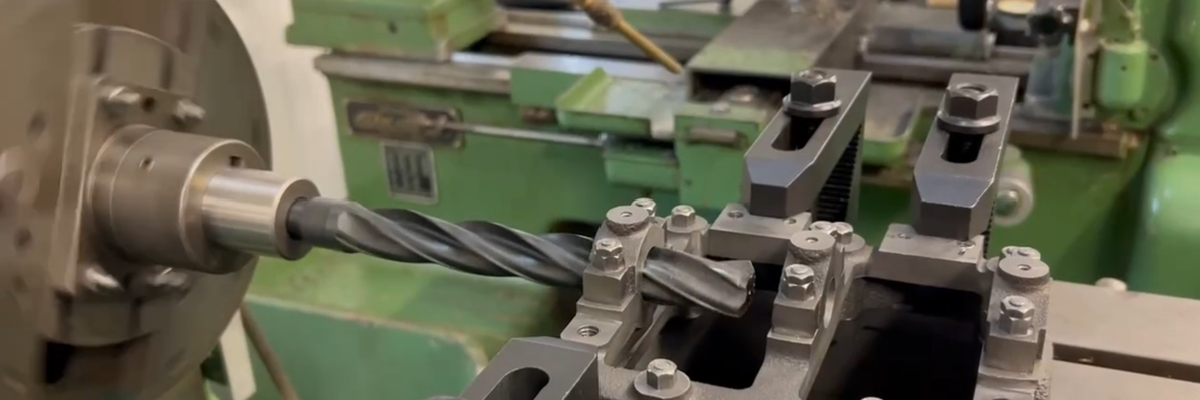

Well as their name would suggest they were invented to drill or finish holes in castings particularly wonky tapered cored passageways. They are part of the family of slot drills, end mills and D bits. They are in effect a very robust 3 or 4 flute drill with a shallow point angle and usually made in cobalt HSS for toughness. I have never seen a carbide one but for our purposes would think them too fragile.

They are used exactly the same as a conventional two flute twist drill keeping the speed and feed towards the lower end of the recommended values. It is quite staggering to see, the first time one is used, that they track a straight path through whatever weird “hole” one of trying to tidy up. The surface finish is better that a twist drill but not as good as a reamer. They can be obtained in many sizes (6mm upwards) but beware that outwith of whole mm increments (or imperial increments) they may be regarded as specials with a special price tag!

Three flute core drills can theoretically remove more material than a four flute version and are better for deeper holes. They might also be better for small diameter holes. Four flute versions give a better surface finish and are easier to re-sharpen. Either way don’t try removing more than 60% material for the diameter of the drill being used. Sequential core drills can of course be used. I don’t have any other than 4 flute versions. They are stocked by most engineering merchants and whilst relatively expensive are worth their weight in gold when they salvage an expensive casting or workpiece. Treat them like reamers and don’t let them come into contact with other hardened tools.